Tatiana Muñiz, UC Davis

Coffee is the most consumed beverage in America (and third-most in the world), yet it is poorly understood. UC Davis researchers across the sciences and humanities disciplines are demystifying the drink — and coming up with ways to make it more delicious and sustainable — in the only university coffee lab in the country.

The UC Davis Coffee Center, conceived (where else?) over a cup of coffee and opened in May, is working with the $28 billion American coffee industry to tackle challenges such as sustainable farming, grading bean color and measuring consumer taste preferences.

Why research coffee?

Despite coffee’s global popularity, coffee research has been underfunded.

Researcher Irwin Ronaldo Donis-González, assistant professor in biological and agricultural engineering and director of Latin American affairs for the Coffee Center, said he is surprised by how little is known about coffee.

“It’s almost like coffee is an untouched crop,” Donis-González said. “There’s been very little research in coffee, believe it or not, even though it’s one of the most exchanged commodities in the world.”

Now, UC Davis is filling that knowledge gap.

“The goal for the Coffee Center is for UC Davis to become the global leader in coffee studies, science, research and education,” said Bill Ristenpart, engineering professor and co-director of the Coffee Center. “Eventually, I want to have all kinds of coffee-related classes in this building. I want this to serve as a hub, a nexus for all coffee-related topics across campus.”

While the Coffee Center building is new, UC Davis’ body of coffee research is not. People familiar with UC Davis have called its group of coffee researchers “the Coffee Center” colloquially for years.

Timothy Styczynski, a professional micro-roaster who owned and operated Bridge Coffee Co., had been following the growth of UC Davis’ coffee research since 2016 and was an early Coffee Center donor in 2021. He was drawn to the Coffee Center because of his decades-long passion for coffee and the potential for new research.

“The research the Coffee Center has been doing is really revolutionary,” Styczynski said. “It’s the first of its kind. I hadn’t seen scientifically published papers diving into coffee. I knew that even though we’ve been [making] coffee for centuries, for us to be able to continue for centuries and beyond, we really have to focus on education. We’ve enjoyed coffee. Now it’s time to study it.”

Styczynski is now the Coffee Center’s head roaster. He manages the center part-time, participates in its research studies and roasts bags of coffee to sell in the campus bookstore. He is also a certified Q grader, one of fewer than 600 in the United States. The certification is internationally recognized in the coffee industry and is akin to a sommelier for wine.

Coffee engineering: The nation’s first coffee course

At UC Davis, the idea of a coffee class came well before the creation of the Coffee Center building. Over a cup of coffee in 2013, Ristenpart and Tonya Kuhl, who is also an engineering professor and now co-director of the center, brainstormed ways to get students more interested in chemical engineering.

Together, they created the first regularly offered, university-level course about coffee in the nation, “The Design of Coffee.” Only 18 students enrolled at the time. This academic year, 2,091 students signed up.

Unique among American universities, UC Davis has a laboratory dedicated to coffee. Each week, students in “The Design of Coffee” learn an engineering concept in their lecture that they then apply in the coffee lab. In their final week, students must brew the best-tasting coffee using the least amount of energy.

Students enter the course with various levels of coffee knowledge and experience. By the end, they learn everything from reverse engineering a drip coffee brewer to understanding coffee as a colloidal fluid.

“Colloid is just a fancy word for ‘a very small particle’,” Ristenpart said. “Coffee is technically a colloidal suspension, which means it’s mostly water with little bits of solid floating around. For the colloid section of the course, students must answer the question: How do we push water through coffee grounds?”

Colloids are so miniscule they can’t be seen with the naked eye, but the quantity and nature of the colloids can affect the mouthfeel and flavor of coffee.

For example, pouring boiled water straight over coffee grounds results in a thick, gritty drink. This is the technique used to make Turkish coffee. After drinking a cup of Turkish coffee, there are enough spent grounds left at the bottom to perform tasseography — fortune-telling using coffee grounds.

“Turkish coffee is totally not filtered, so that’s one extreme,” Ristenpart said. “Most American drip brews use the paper filter. And there’s other techniques where you can have really, really filtered coffee, so no colloids at all or very few.”

Because there are about 1,000 different flavor molecules identified in roasted coffee, understanding the many chemical engineering concepts — like colloidal fluids, mass balances and transfer, pH levels and fluid flow within geometric shapes — in the coffee-making process is important for coffee companies that want to make a superb product.

For Sage Ikeda, a second-year mathematical analytics and operations research major, taking “The Design of Coffee” helped him realize the many career opportunities available in the coffee industry. He now works part-time at the Coffee Center.

“Before taking the coffee class, I never thought about pursuing a career in coffee,” he said. “For me, it was like, ‘Oh, coffee is just the thing I nerd out about for 20 minutes in the morning.’ But after, I realized coffee is a pretty big industry. It would be pretty cool to work in coffee.”

Today, “The Design of Coffee” is well-known among UC Davis students and has been included in many class bucket lists for years. The rapidly growing popularity of the course combined with interest from the coffee industry led to the creation of the new Coffee Center.

Coffee farming versus coffee consumption

Coffee comes from plants that grow small, round fruit called coffee cherries that grow in bunches like grapes.

But, unlike grapes, it is difficult for coffee plants to thrive in the United States. If temperature levels drop below freezing, even for a single night, it could kill the plant. So, most coffee is grown in tropical regions on the sides of mountains, far from most Americans.

Just a few decades ago, many American coffee importers had never stepped foot on a coffee farm, and coffee farmers in another country may have never tasted a cup of coffee.

“A lot of the hard work that goes into coffee is out of sight, out of mind,” Ristenpart said. “It’s literally in a different continent, across a language divide. Imagine trying to improve the quality of coffee when there’s zero feedback loop.”

Coffee Center researchers like Donis-González are trying to close that divide. He is currently on sabbatical researching coffee farming in his native Guatemala. His main research interests are in how coffee is handled after harvest, tracking produce from field to consumer and reducing energy consumption during processing.

Laudia Anokye-Bempah, Coffee Center researcher and Ph.D. candidate in biological systems engineering, was not a coffee drinker when she lived in her native Ghana. She noted how people from countries that produce the most coffee do not drink it because the focus is on growing coffee rather than roasting it. She said she believes farmers could flourish economically with high-quality roasting education.

Styczynski encouraged coffee consumers and researchers to keep coffee farmers in mind.

“The 25 million families that grow coffee around the globe don’t have many other means for sustainability in their community,” Styczynski said. “People who buy coffee are also putting shoes on coffee farmers and their families, food in their bellies, and providing medicine. And the better we can take care of the plants, the better we take care of the communities that grow and sell them.”

Food waste and coffee sustainability

Coffee Center researchers also are tackling food waste. After coffee beans have been collected from the cherries, the remaining skin and pulp, called cascara, is often discarded.

“It takes three years after planting a seed for a coffee tree to mature to the point where it’s producing fruit,” Ristenpart said. “Three years! Three years of maintaining it. So, you do all this growing, pruning, fertilization, spraying. A tremendous amount of labor goes into it, and then finally somebody goes and picks by hand all the coffee cherries. And the very first thing they do is deliver it to a wet mill, where they then strip off half the mass, like all the fruit. It’s kind of crazy because the fruit has caffeine, it’s got a tremendous amount of antioxidants.”

Some cascara is dried and turned into tea, but Ristenpart likens this process to trying to create wine out of raisins. The resulting drink tastes like oxidized, dry fruit.

Melina Devoney and Timothy Buensalido, UC Davis alums in international agricultural development, researched whether cascara could be upcycled — recycled at a higher value — by turning it into jelly. Their hope is to reduce waste and provide farmers with more revenue.

“Coffee farmers face constant economic stress and uncertainty,” Devoney wrote in a blog post about her research for the Department of International Agricultural Development. “Most farmers earn only a few dollars per day.”

They conducted sensory surveys at the Coffee Center, which resulted in high liking scores. This means cascara could be made into a marketable jelly product that would likely sell well.

Ristenpart, who worked with Devoney on the research project, has become passionate about the topic, trying cascara on a variety of food products.

“You take the fresh fruits immediately out of the de-pulper and throw it into a pot of boiling water to extract the caffeine, the sugars, the yummy fruit flavors,” he said. “And then you add a bit of sugar and a bit of lemon juice, and you make this fantastic syrup that works using soda products or tastes really good in a cascara daiquiri.”

Ristenpart wanted to show his students a coffee farm without flying them to another country. So, he took them on a camping trip to a rare American coffee farm located in Goleta, California, north of Santa Barbara, where coffee is grown under the protective shade of avocado trees.

“There, we made blueberry pancakes and drizzled the cascara syrup on top. It was fantastic,” he said.

He said he hopes to someday build a greenhouse behind the Coffee Center, where students can grow their own coffee plants, like how UC Davis’ Robert Mondavi Institute for Wine and Food Science has a vineyard in its backyard.

Coffee bean storage and preservation

The Coffee Center’s Green Bean Storage Laboratory, funded by Nicaraguan Coffee Growers, is lit with natural light and is spacious, with concrete floors, white walls, an industrial ceiling and a variety of bags and boxes brimming with green coffee beans on warehouse shelves.

Green coffee beans have not been roasted. They smell light and fruity, almost like hay. They are smooth and pistachio-colored but feel nothing like pistachios.

“If you ate one of these green ones uncoated, it’d break your teeth in half,” Kuhl said, holding a bean up between her thumb and forefinger.

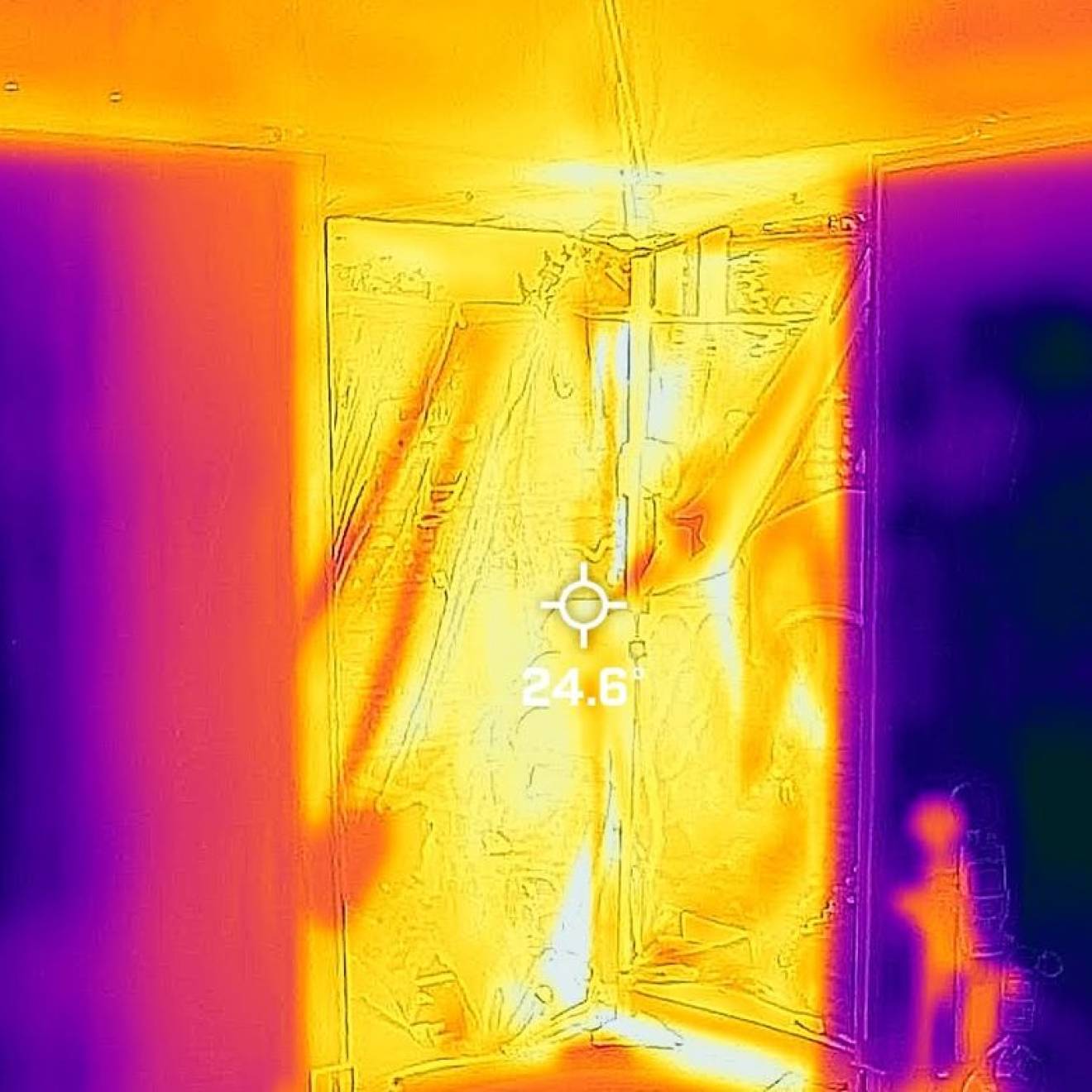

On the wall opposite the shelves are fridges, which are used to preserve coffee bean flavors, and environmental chambers, used to test different humidity and temperature levels.

“When you ship coffee from Uganda, that’s a land-locked country. So, the coffee could be sitting in high temperatures for months before it gets shipped to Oakland,” Kuhl said.

Researchers at the Coffee Center use the environmental chambers to test similar scenarios using small batches of coffee beans. Then the degraded coffee is tested by a sensory team, determining exactly how much degradation over time affects flavor.

“Our goal in testing bean degradation is to see which strains are highest quality,” Kuhl said. Determining this could save coffee growers and shippers significant money and time.

Testing coffee sourness

Adjacent to the storage lab is the Peet’s Coffee Pilot Roastery. Inside are two large roasters, one Aggie Blue and the other Aggie Gold. Styczynski feeds green coffee beans into the blue roaster.

“In the roasting, I can manipulate how sweet the coffee is, how sour it is, how roasty it tastes, if it’s thinner or heavier in body and mouthfeel from the same beans using different recipes,” he said.

He checks the roast using sound and smell. Roasting coffee beans sounds like popping popcorn and, surprisingly, does not smell anything like brewing coffee. The smell is more warm, light and soft than the smell of a coffee shop.

“I love smoked salmon, but I want to taste salmon, not smoke,” Styczynski said. “In the same way, I want to not only taste smoke in my coffee.”

He pulls out the sample tryer, a little scoop built into the side of the roaster that has some of the beans from that point in time. Roasters look at and smell the beans in the sample tryer to decide when to drop all the roasting beans into the cooling tray.

Styczynski has done this process of roasting and checking countless times while working alongside Anokye-Bempah to conduct research in the Coffee Center.

Anokye-Bempah’s first research paper is about how a coffee’s roast profile — the temperature versus time inside the roaster — affects the perceived sourness of the resulting coffee.

“Roasting takes about 12 minutes or so, and we did a 16-minute roast, so super dark, pulling samples every minute across that profile in a production roaster, which had never been done before,” Styczynski said.

For six months, Anokye-Bempah and Styczynski produced a variety of roasts, pulling a sample per minute and dropping the samples into liquid nitrogen to freeze the chemical process in time. They gathered thousands of samples of beans from various points along the roasts for different roast profiles.

Their findings?

“We were able to see seven different recipes in triplicate, that the peak always happened statistically at the same time regardless of coffee origin, coffee bean and coffee roast,” Styczynski said.

In other words, “Our results provide insight on how to manipulate and achieve desired sourness during roasting,” Anokye-Bempah said.

Now, roasters can tailor their roasts to create a cup of coffee with the perfect balance of acidity.

A new universal coffee color grading scale

Just as coffee beans come in thousands of different flavors, they come in thousands of colors, and the coffee industry has had a hard time categorizing those colors.

“Right now, if you say, ‘medium roast,’ it could mean anything under the sun,” Ristenpart said. “One roaster’s ‘light roast’ could be darker than another roaster’s ‘dark roast’.”

Anokye-Bempah’s second research paper, which is in review, aims to solve this industry-wide problem. The paper is titled, “A Universal Color Curve For Roasted Coffee.”

“It turns out when you take coffee beans, regardless of the roast profile, and plot the color in something called the C-LAB, everything falls in this beautiful three-dimensional curve that I’m hoping becomes known as the Anokye-Bempah Curve,” Ristenpart said.

He is working with the Specialty Coffee Association on creating a universal coffee color grading scale based on Anokye-Bempah’s findings. So, coffee roasters around the world will finally have a science-based tool to categorize their roasts very soon.

Coffee quality control using new tech

After coffee cherries are picked and the beans are dried, they are sorted and graded through a quality control process, which until now has been complex and inefficient.

Ristenpart recalled seeing the traditional quality control process in action at a coffee dry mill, where operators stacked sieves and shook green coffee beans through them to get the correct size distribution.

“You put the beans in. Then they have smaller and smaller holes. Then you take them out and then weigh each tray. It seemed like a huge pain,” Ristenpart said. “I said, ‘Why don’t you just take a photo and measure that way?’ They said, ‘Well, that’d be great.’”

Then, in 2022, he met two computer science students who could turn his idea into a reality. Ph.D. candidate Xiao Liu and fourth-year Zhuoheng Li are Q-certified graders passionate about coffee and technology.

Together, Liu and Li built Roastpic, a coffee vision grading system using artificial intelligence that allows users to grade coffee beans by taking photos of them on a smartphone. The app can determine coffee bean size, color and defects in a snap, significantly decreasing the time and cost it takes for coffee graders to filter out low-quality coffee beans.

Roastpic has three versions: a basic version for hobbyists, a premium version for advanced graders and a newly released professional version for coffee industry professionals.

Since its founding, the tech company has grown to a team of 10, composed entirely of faculty and students from the Coffee Center.

Keegan Thompson, a fourth-year communication major, had been working as a Philz Coffee barista for only a few months before Ristenpart came into the picture, recognizing him for his communication skills. Thompson now has the title of customer service expert at Roastpic and has become fully immersed in coffee science.

“After working at Roastpic for a couple of months, I wanted to get more involved in the coffee field,” Thompson said. “So, when the center here opened, I was excited to get involved. I asked [Styczynski] if he was able to teach me how to roast coffee. From there, I got an internship and a part-time job working here.”

A class in coffee tasting and consumer preferences

Thompson is a teaching assistant for the first class held solely at the Coffee Center, “Coffee Tasting Practicum,” an experimental, one-unit course focused on coffee as a sensory experience. He works directly with co-teachers Ristenpart and Styczynski, setting up lab equipment and making lots of espresso.

“What we’re doing in the course is exploring product development and introducing students to how you think of product development, how you design a blend,” Ristenpart said.

On a crisp Friday morning, about 10 students file into the John and Gina Wasson Classroom in the Coffee Center, pouring themselves a cup of coffee specially brewed by Styczynski to taste before taking their seats.

Styczynski describes the type of beans and brewing process used and asks the class for their thoughts on the coffee’s flavor before a teaching assistant flips through the slides of a presentation titled, “Holiday Blends.” Over the past several weeks, the students have been tasting different holiday blends and learning how to make their own.

“The holidays are coming up, so we want to have a limited-edition holiday blend for sale at the campus bookstore,” Ristenpart said.

The tasting process is not a matter of personal preference, though. The final choice of what holiday blend to sell must be based on consumer hedonic preference testing, a quantitative method in sensory science that measures how much consumers like a product.

After finishing their cups of coffee, the students head into the Sensory and Cupping Laboratory, a sleek café-styled room with a service window connecting to the La Marzocco Brewing and Espresso Laboratory. Styczynski and the teaching assistants brew mugs of coffee and slide them through the window to be freshly served to those in the sensory lab.

Five students file into the small sensory room and take seats in individual booths. The room would be pitch dark without the red lights shining overhead, which help mask color differences in the coffees. This allows the students to focus only on the coffee’s flavor, smell and texture.

Thompson opens a small service door in front of each booth to slide in a single mug of hot coffee on a plastic tray. When all the doors are shut, the students take their time sipping coffee while scrolling on their dimly lit phone screens.

The students are not on their phones to pass time. They are conducting CATA — check all that apply — testing to make scientifically informed word clouds of flavor descriptors. The form contains a long list of flavors with checkboxes beside each one. The students select as many flavors as they can taste from options like citrus, caramel, floral, vegetal, nutmeg and cardboard.

“You know how on a bag of specialty coffee, there’s always three different words describing the flavor? And you think, ‘Do they just pull those out of a hat?’” Ristenpart laughs. “There’s a way coffee makers can choose those words more rigorously — by seeing which words pop in the CATA testing.”

When finished, each student flips a switch in front of them, and Thompson retrieves the empty mugs. The students then make their way to the brewing room to learn how to make that week’s drink, a peppermint mocha latte complete with a small candy cane for both taste and garnish.

Toward the end of the session, the students head back into the classroom to see their tasting results. On the projection screen, a bar chart reveals the blend’s most-perceived flavors: caramel, nutmeg and baking spices. Only two students chose potato, and none chose cardboard.

The class agrees this blend was one of the best so far. The last one, Blend 715, did not do as well. It had rough hedonic scores, and its word cloud emphasized the flavors “bitter,” “very bitter” and “bread” in enormous font, decidedly not the ideal coffee to sell at the bookstore.

The students in the “Coffee Tasting Practicum” enjoy the course for the free coffee, but they also appreciate how approachable it is for anyone who might feel nervous taking a chemical engineering class.

“I think the Coffee Center makes a field that can be somewhat hard to understand really easy and accessible,” Thompson said. “Back when I started learning about coffee, my knowledge was basically nonexistent. And now, I’ve only been working with coffee for the past six or seven months. But my knowledge has skyrocketed. It’s so amazing to learn all the stuff they’re teaching here, and even being in the class I’m TA’ing for, I’m learning new things, which is such a fun experience.”

Elevating coffee at the global level

Ristenpart said he aims to develop a course held at the Coffee Center in which the “Coffee Tasting Practicum” will be one module in a larger, more formal class that goes more in depth about the physical and chemical processes in coffee. This future course will be the first of many to come.

The multidisciplinary nature of coffee has already attracted over 50 UC Davis faculty members across a variety of backgrounds and research interests that span from agricultural sustainability to the effects of coffee consumption on human health.

But despite coffee being so popular and economically profitable, the numbers are not reflected in academic funding for coffee research. Seeing a gap, industry professionals are continuing to step up to provide philanthropic support.

“We believe the Coffee Center will create a new pipeline of talent and really elevate the coffee industry to something that’s more akin to the beer industry or the wine industry,” said Scott Callender, former vice president of marketing and consumer strategy for La Marzocco.