Aliyah Kovner, Berkeley Lab

A multidisciplinary Berkeley Lab team has been working for several years to develop a game-changing plastic that, unlike traditional plastics, can be recycled indefinitely and is not made from petroleum.

Their latest milestone was the release of an analysis showing the feasibility and potential outcomes of launching the unique material, called poly(diketoenamine) or PDK, into the market at an industrial scale.

The team found that making products out of recycled PDK could quickly become as cheap as making the same item with new plastic polymers (a very small proportion of our current plastics are recycled, so most products are made from “virgin” plastic resin), while also reducing CO2 emissions and energy requirements of manufacturing. Furthermore, the scientists plan to develop a process to create the initial PDK resin using microbe-fermented plant material, meaning that the entire lifecycle of a PDK plastic product could be low-carbon or even carbon neutral.

Once the infrastructure for large-scale PDK production and recycling is developed, the scientists envision that PDK could replace traditional plastics in a variety of consumer products, from car parts to water bottles.

We spoke with two project leaders, Brett Helms and Corinne Scown, about the inspiration for PDK, shortfalls in our current recycling systems, and how this ambitious project is enabled by a diverse combination of scientific expertise.

Brett Helms is a chemist and fabrication scientist working at Berkeley Lab’s Molecular Foundry, a U.S. Department of Energy (DOE) user facility. Helms led the group that invented PDK more than three years ago, as part of a Laboratory Directed Research and Development (LDRD) Program project focused on creating a highly functional plastic alternative.

Corinne Scown is a scientist in Berkeley Lab’s Energy Technologies Area, and Vice President for the Life-cycle, Economics, and Agronomy Division at the Joint BioEnergy Institute (JBEI) – a DOE Bioenergy Research Center. Scown, an expert in the field of technoeconomic analysis, leads the design and development of processes for industrial-scale PDK production and recycling. By modeling how these systems would work on a large scale, her work identifies potential bottlenecks and predicts both cost and environmental impact, thereby helping materials scientists select the most efficient and sustainable technologies from an early stage.

The project’s other leaders are Jay Keasling, the CEO of JBEI; and Kristin Persson, Director of the Molecular Foundry.

Q. Brett, where did the idea or inspiration for PDK come from?

Brett: The way industry practices polymer recycling is changing. Currently, the approach relies on mechanical recycling where, after sorting and grinding, polymer waste is melted into a homogenized material whose characteristics have degraded along the way. In the future, chemical recycling is expected to play a bigger role, as it prioritizes recovery of high-value materials that can be reused in manufacturing. However, with current chemical recycling technology, very few polymers can be efficiently recycled, whether we measure efficiency on the basis of the energy required, the amount of CO2 emitted, or the amount of pristine material we recover for secondary resin manufacturing. We were aware of these challenges and approached the problem from that perspective. We tried to design PDKs as next-generation polymers that require only small amounts of energy to be chemically recycled back to their original monomers with high yields, such that carbon in PDKs can be recirculated across limitless cycles of remake-and-reuse.

Q. Corinne, what drew you to this work?

Corinne: I’ve done work on technoeconomic analysis and life-cycle assessment of biofuels for years now and, believe it or not, plastics are not a huge leap. We’ve been exploring bio-based products for some time now, and biopolymers were already interesting to us because we know that it’s crucial to find renewable alternatives for all the different products we make from the typical barrel of oil, not just fuels. Brett and Jay pulled me in when they were writing the proposal for this particular project and I was floored by the clarity of vision and how quickly it all came together. The idea of a polymer that can be recycled back to virgin-quality monomers with minimal energy input solves a lot of otherwise intractable problems with plastic waste.

Credit: Peter Christensen/ Berkeley Lab

Q. Brett, how did you get into materials science? Was there always a goal to create environmentally conscious materials, or did you start out with another goal?

A GIF showing how PDK plastic readily breaks down when put in an acidic solution. The acid breaks the bonds between the resin monomers and separates them from the chemical additives (which give plastic its look and feel) so that the monomers can be 100% reused in a new product. (Credit: Peter Christensen/ Berkeley Lab)

Brett: I did undergraduate research with Shenda Baker at Harvey Mudd College, where we were studying the physics of polymers at interfaces. At some point, I realized that if I wanted to study interesting polymers, I might need to learn how to make them myself. Shenda introduced me to Craig Hawker, and I spent time learning polymer synthesis from him and Eva Harth at the IBM Almaden Research Center. Feeling more confident in my synthesis abilities, I then became interested in learning how to design function into polymers. That’s what led me to UC Berkeley, where I conducted my Ph.D. with Jean Fréchet, whose group was well known for its creativity in functional polymers. I also learned, in my postdoc with Bert Meijer, at the Eindhoven University of Technology in the Netherlands, how interactions between polymers and other materials are central to their function.

Working at a National Lab has really opened my eyes to the breadth in which materials make a difference in our lives, and increasingly in the sustainability of our life-choices. I hope that, in our work with rethinking polymer chemistry for the circular economy, we offer creative solutions that everyone can get excited by and learn from, and that people might be motivated to work with us to bring those solutions to the world, in line with our mission here at Berkeley Lab.

Q. Corinne, the term “technoeconomic analysis” is probably new for a lot of people. How do you explain what you do when a non-scientist asks?

Corinne: Technoeconomic analysis, or TEA for short, is one of those terms that didn’t get used much a decade ago and it’s a lot more common now. At a basic level, TEA involves engineering design and cash flow analysis. The engineering design and simulation is usually the hard part. You’re taking a cool result someone got in the lab and trying to figure out what a commercial-scale facility would look like, including everything from solvent recovery to heat and power generation to waste handling. This usually involves thinking through things that the scientists haven’t considered and it can raise interesting questions. For example, TEA showed that one of the reactants in the discovery-based chemistry for synthesizing virgin PDK – N,N’-dicyclohexylcarbodiimide (DCC) – proved to be pretty expensive, emissions-intensive, and it resulted in the generation of hazardous waste from the process. You could say that DCC had a target on its back after that – Brett’s team was set on finding a way to reduce or eliminate its use.

Q. A lot of people get confused about plastic recycling. For example, what’s recyclable versus what isn’t? What happens to it after you put it in the bin? Do you have any advice right now, before PDKs or other truly recyclable plastics hit the market, for people trying to be mindful about the materials in their lives?

Corinne: Fortunately, the issue of plastic recycling is getting a lot more attention lately and there are great news stories you can read or watch to get surprisingly nuanced takes on what is or isn’t recyclable. I think the main misconception is that we all have a duty to put anything that has that little recycling logo into the recycling bin. In fact, that just means facilities that are space- and capacity-constrained in the best of situations may have to process more material that will ultimately go to landfills. The best thing you can do is avoid generating waste in the first place, when possible. However, at the end of the day, we have to be practical. People, myself included, want to do what is convenient. When I do have a plastic item I need to throw out, I ask myself a couple of basic questions: First, is the plastic labeled #1 (PET) or #2 (HDPE)? Secondly, is it three-dimensional (not flat)? If the answer to either of those questions is “no,” I stick it in the trash. The vast majority of the mixed #3–7 bales end up going to landfills, and if you try to recycle flat stuff – like plastic film and plastic envelopes – those have a good chance of ending up as a contaminant in otherwise pretty high-value paper or cardboard bales. If the fiber bales are too contaminated, they might not be accepted. So “wishcycling,” as they call it, can have some very real negative consequences.

Brett: The pandemic has changed our understanding for how much plastic we use and how hard it would be to reduce. Working more from home, we see exactly how much waste we generate, whereas when we were previously on-the-go, travelling between many places, our daily waste was spread out across bins that other people empty. Absent any sort of regulations on plastics use and end-of-life producer responsibility, the strongest impact we may have could be through harnessing our purchasing power by buying products that are made with high post-consumer content or bio-sourced materials, or are made from the highly recyclable polymers like PET. Similarly, we could make choices not to buy products that would be difficult to recycle – for example, those made from mixtures of several kinds of plastics. Making informed choices is hard, as Corinne mentioned. There’s a lot of “wishcycling” that happens to the best of us. It’s easy to be duped into thinking something is sustainable if it has a recycle logo on it somewhere. For decades, we have been led this way, and it will take time to reorient our thinking with sustainable re-use in mind.

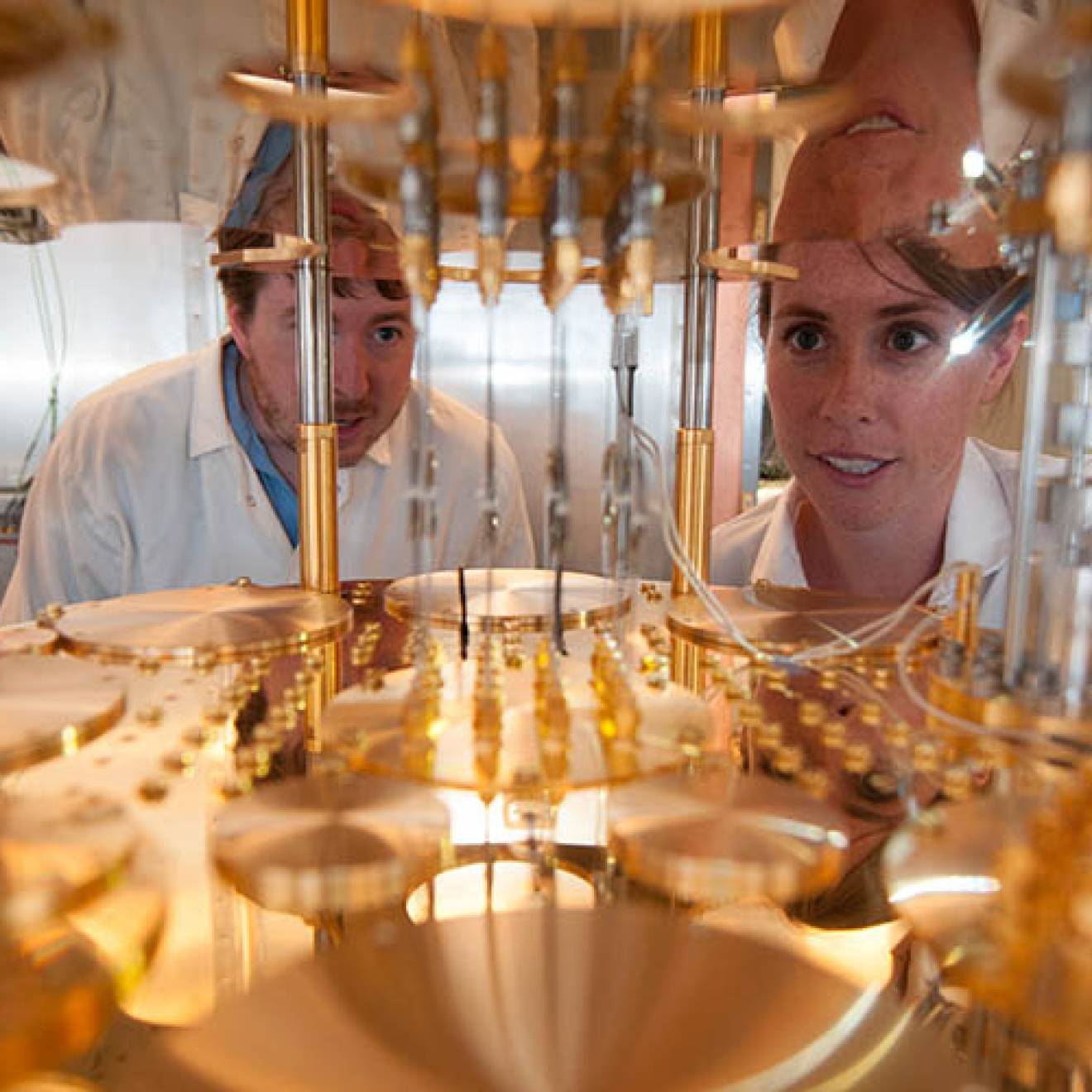

Berkeley Lab scientists Brett Helms (right) and Corinne Scown examining PDK samples at the Molecular Foundry. (Credit: Thor Swift/Berkeley Lab)

Credit: Thor Swift/Berkeley Lab)

Q. Tell us about a personal highlight from the last couple of years!

Brett: I have never experienced anything like the public response to our report on infinitely recyclable PDK materials. It was posted online on Earth Day in 2019, when the awareness surrounding the impacts of plastic waste was becoming part of a global collective consciousness. Within hours, Berkeley Lab was fielding inquiries from the media, which resulted in a year-long engagement with them to bring clarity to the plastics problem and the urgent need for solutions. It was also clear that there was a growing community from around the world and from different backgrounds, all focused on working together.

Corinne: For me, visiting waste management facilities was a real highlight, and it is something I’ve missed during the pandemic. In the last few years, I’ve been to a materials recovery facility (MRF), a composting facility, and multiple anaerobic digestion facilities. There is something special about going there and seeing the equipment in action, seeing what a plastic bag looks like after it has been through a digester or a composting process. At the MRF, they talk about companies that take their new packaging and send it through the facility as an experiment to see where it ends up. It’s a whole different world and most people don’t get to see it.

Q. What excites you most about the future of the collaboration?

Corinne: This project has been one of the most fun and fulfilling experiences in my career at Berkeley Lab so far. I like the idea of digging into an application that makes sense for PDKs, like automotive parts or electronics, and figuring out how to implement it in practice. It gets into all sorts of interesting infrastructure issues. Cars have a very different end-of-life than consumer electronics, for example. Would we want to let shredder facilities just shred vehicles, recover the metals, and then process the mixed material to recover PDKs, or should we try to pull out parts with PDK for recycling beforehand? What car parts make the most sense for PDK? I don’t know the answer to those questions yet, but I want to find out. I have no doubt that Brett, Jay, and Kristin can figure out how to hit the necessary specifications and tune each type of PDK so it depolymerizes at just the right conditions. My favorite thing to do is take those cool results and figure out how they can work at scale.

Brett: I have learned so much working with this team. This is one of those projects where together, we are greater than the sum of our parts. I’m looking forward to understanding how PDKs might be tailored for specific applications and scaled. That’s where our work with Corinne has been very insightful. I also look forward to working with Jay and Kristin on making PDKs from bio-based ingredients. There’s a growing interest in highly recyclable bio-based plastics, and Jay and Kristin’s efforts have been aimed at providing a competitive edge to both performance and recycling efficiency. The students and postdocs working on this project are endlessly creative and bring life to all of the ideas that come from our discussions.

The ongoing PDK plastic project is funded by DOE’s Bioenergy Technologies Office and Berkeley Lab’s Laboratory Directed Research and Development (LDRD) program.

The PDK technology is available for licensing and collaboration. If interested, please contact Berkeley Lab’s Intellectual Property Office, ipo@lbl.gov